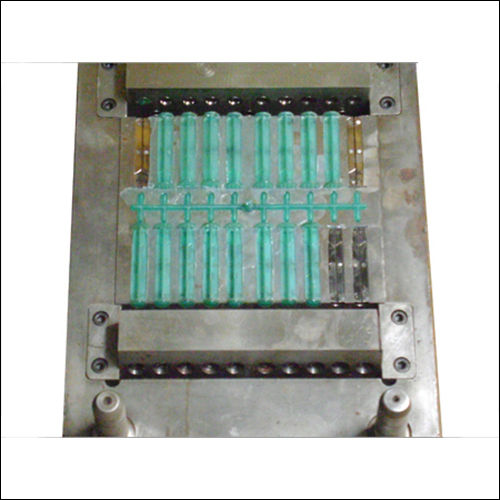

Syringe Plunger Mould

Syringe Plunger Mould Specification

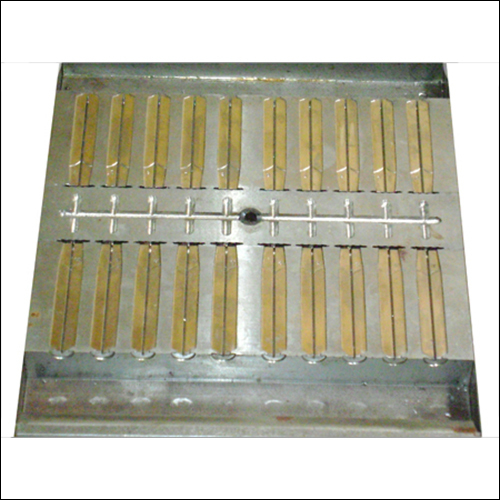

- Mold Base

- P20 Steel

- Molding Material

- High Quality Stainless Steel / ABS (as per client requirement)

- Shaping Mode

- Injection Mould

- Material

- Tool Steel, Hardened Steel

- Tolerance

- 0.02 mm

- Mould Life

- 1,000,000 Shots+

Syringe Plunger Mould Trade Information

- Minimum Order Quantity

- 1 Set

- Payment Terms

- Cheque

- Packaging Details

- As per requirement

- Main Domestic Market

- All India

- Certifications

- An ISO 9001:2000 Certified company :

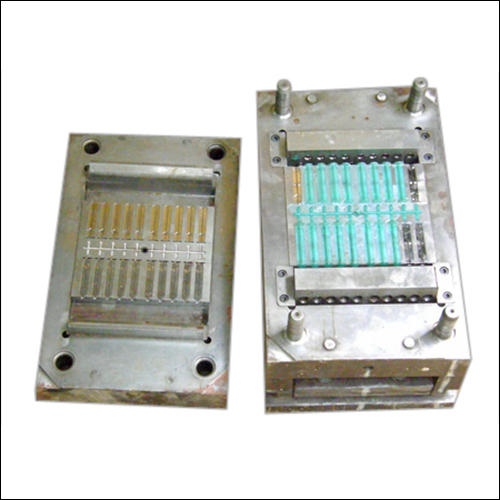

About Syringe Plunger Mould

Working on ethical business policies, we have been able to emerge as a reputed name in the domain of manufacturer, supplier and exporter of high quality Syringe Plunger Mould. These plunger moulds are manufactured in accordance with set quality standards using hi-tech machines of our manufacturing plant. Furthermore, our complete manufacturing process is undertaken in supervision of quality controllers. Quality approved at various levels of manufacturing and post manufacturing, our offered SyringePlunger Mould can be availed in various sizes.

Key Features:

- Leak proof function

- Accurate dimensions

- Rugged construction

- Longer functional life

High-Precision Medical Moulds

Designed with meticulous accuracy, our Syringe Plunger Moulds achieve a dimensional tolerance of 0.02 mm, ensuring consistency and reliability. Utilizing advanced injection moulding techniques, our products meet the stringent requirements of the medical industry, providing both durability and smooth operation for mass syringe production lines.

Customizable Materials & Applications

Choose between superior stainless steel or ABS for moulding, depending on your medical application and performance expectations. The versatility of materials allows for compatibility with various types of syringes, delivering optimal results whether you aim for strength, chemical resistance, or cost-effectiveness.

FAQs of Syringe Plunger Mould:

Q: How is the Syringe Plunger Mould manufactured to ensure high accuracy?

A: The mould is produced using precision machining on a P20 steel base, with tool or hardened steel inserts, and advanced injection moulding techniques. This combination ensures a tight tolerance of 0.02 mm for reliable, repeatable performance.Q: What moulding materials can be used, and how do I select the right one?

A: We offer high-quality stainless steel and ABS as molding materials. Your choice depends on the end-use: stainless steel provides greater strength and chemical resistance, while ABS offers lightweight and cost-effective options. Our team can help recommend the best material for your requirements.Q: When should I replace the Syringe Plunger Mould?

A: With a mould life exceeding 1,000,000 shots, replacement is only needed after extensive use. Regular maintenance and inspection further extend the operational lifespan, reducing long-term production costs.Q: Where can the Syringe Plunger Mould be used?

A: Our moulds are primarily intended for manufacturing plastic syringe plungers in large-scale pharmaceutical and medical device production facilities. They are suitable for both domestic and international manufacturers looking for high-output, reliable mould solutions.Q: What is the process for ordering a customized mould?

A: Simply provide your specific syringe plunger requirements, including preferred materials and dimensions. We will collaborate with you through design, prototyping, and production stages, offering technical support every step of the way.Q: How does using your mould benefit syringe manufacturers?

A: Manufacturers benefit from high-precision, durable moulds that ensure consistent product quality and minimize downtime, thanks to the moulds long shot life and robust construction. This translates to lower overall production costs and reliability with every cycle.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plunger Mould Category

Industrial Syringe Plunger Mould

Minimum Order Quantity : 1 Set

Mold Base : High Precision Stainless Steel

Material : Other, P20 Steel / S136 Steel (Core and Cavity)

Tolerance : 0.01 mm

Mould Life : Minimum 1 million shots

Plunger Mould

Minimum Order Quantity : 1 Set

Mold Base : High strength steel

Material : Other, Alloy steel

Tolerance : 0.02 mm

Molding Material : Plastic, rubber, or metal (as per application)

Send Inquiry

Send Inquiry