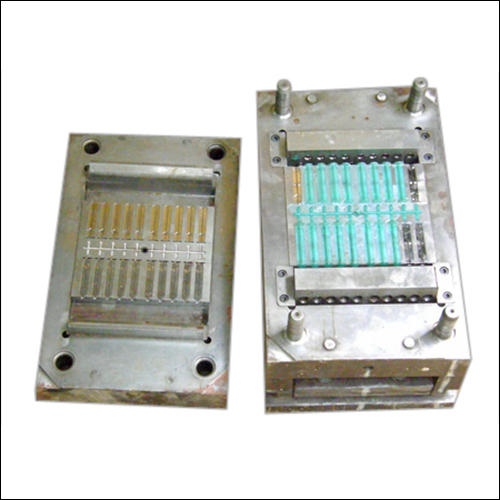

Plunger Mould

Plunger Mould Specification

- Cavity

- Single or multiple, custom as required

- Mold Base

- High strength steel

- Molding Material

- Plastic, rubber, or metal (as per application)

- Material

- Alloy steel

- Tolerance

- 0.02 mm

Plunger Mould Trade Information

- Minimum Order Quantity

- 1 Set

- Payment Terms

- Cheque

- Packaging Details

- As per requirement

- Main Domestic Market

- All India

- Certifications

- An ISO 9001:2000 Certified company :

About Plunger Mould

Established in the year 1995, ours is one of the most prominent organizations engaged in manufacturing, exporting and supplying superior grade Plunger Mould. In order to attain utmost satisfaction of our valued clients, we have been manufacturing these moulds in various sizes and dimensions. Moulds manufactured by us are capable of working for various applications in all temperatures and pressure conditions. We manufacture these moulds using superior angled and floating disc arrangement so as to make it jam and leak proof.Plunger Mould offered by us have following quality features:

-

Perfect dimensions

-

Rugged construction

-

Dimensional accuracy

-

Seamless finish

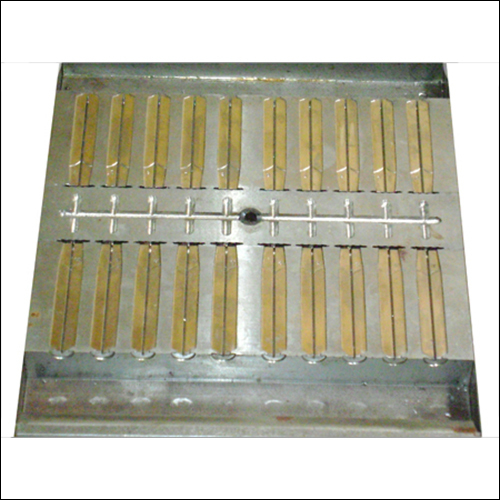

Precision Engineering for Reliable Molding

Every plunger mould is manufactured with high-strength alloy steel and adheres to strict tolerance levels, ensuring consistency and reliability in your production lines. Customization options allow for single or multiple cavities to match your operational scale and requirements.

Versatile Molding Material Options

Our moulds are compatible with plastic, rubber, or metal, making them ideal for industries ranging from automotive to packaging. Material selection and mould design are tailored for optimal results in each application.

Comprehensive Service and Global Export

Based in India, we serve as not just manufacturers, but also as suppliers, exporters, and service providers. Our experienced team supports clients globally, offering technical guidance and after-sales solutions.

FAQs of Plunger Mould:

Q: How is the plunger mould manufactured to ensure high accuracy?

A: The plunger mould is manufactured using state-of-the-art CNC machining and finishing processes. Crafted from high-strength alloy steel, each mould is engineered to a precise tolerance of 0.02 mm, guaranteeing exceptional dimensional accuracy and durability in use.Q: What materials can be molded using this plunger mould?

A: Our plunger moulds are designed for versatility and can be used with plastic, rubber, or metal materials. The selection of the molding material depends on your specific product requirements and application.Q: When should I choose a single cavity versus a multiple cavity mould design?

A: A single cavity mould is ideal for lower-volume or prototyping needs, while multiple cavity moulds are recommended for mass production due to their ability to produce several parts simultaneously, improving efficiency and reducing unit cost.Q: Where do you export and supply these moulds from?

A: We are based in India and export our plunger moulds globally. Clients across various industries rely on our products due to our robust manufacturing capabilities and commitment to international quality standards.Q: What is the process involved in customizing a plunger mould for my application?

A: The customization process starts with understanding your specific needs, such as desired molding material and cavity count. Our engineering team then designs and manufactures the mould, ensuring it meets your precise tolerance, durability, and production expectations.Q: How can this plunger mould benefit my manufacturing process?

A: By using our plunger moulds, you gain higher precision, consistent product quality, and enhanced operational efficiency. Customizable designs further ensure the mould fits seamlessly into your specific process, minimizing waste and maximizing productivity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plunger Mould Category

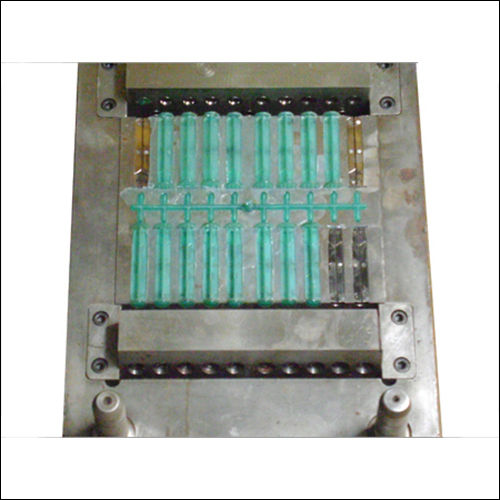

Syringe Plunger Mould

Minimum Order Quantity : 1 Set

Tolerance : 0.02 mm

Mold Base : P20 Steel

Material : Other, Tool Steel, Hardened Steel

Mould Life : 1,000,000 Shots+

Shaping Mode : Injection Mould

Industrial Syringe Plunger Mould

Minimum Order Quantity : 1 Set

Tolerance : 0.01 mm

Mold Base : High Precision Stainless Steel

Material : Other, P20 Steel / S136 Steel (Core and Cavity)

Mould Life : Minimum 1 million shots

Shaping Mode : Injection Mould

Send Inquiry

Send Inquiry