Gasket Syringes Moulds

Price 700000 INR/ Unit

MOQ : 1 Set

Gasket Syringes Moulds Specification

- Molding Material

- Medical Grade Polypropylene / Silicone Rubber

- Mold Base

- P20 Steel, DME Standard

- Cavity

- 12 Cavities (Customizable from 4 to 32 Cavities)

- Shaping Mode

- Injection Mould

- Mould Life

- 500,000 to 2,000,000 Shots

Gasket Syringes Moulds Trade Information

- Minimum Order Quantity

- 1 Set

- Supply Ability

- 2 Sets Per Month

- Delivery Time

- 1 Months

- Packaging Details

- As per requirement

- Main Domestic Market

- All India

- Certifications

- An ISO 9001:2000 Certified company

About Gasket Syringes Moulds

Unlock unrivaled manufacturing efficiency with our Gasket Syringes Mouldsnow with instant savings and offers ending soon. Gain access to valuable, top-ranking solutions for the medical and pharmaceutical industries. Choose between cold or hot runner systems, high polish or mirror finish surfaces, and easy pin ejection. Our moulds are engineered using advanced software like AutoCAD and SolidWorks, with DME/HASCO standard bases and optimized water cooling. With customizable cavities (432) and a robust mould life of up to 2 million shots, these moulds ensure superior performance and easy maintenance, making us a leading exporter, supplier, and manufacturer in India.

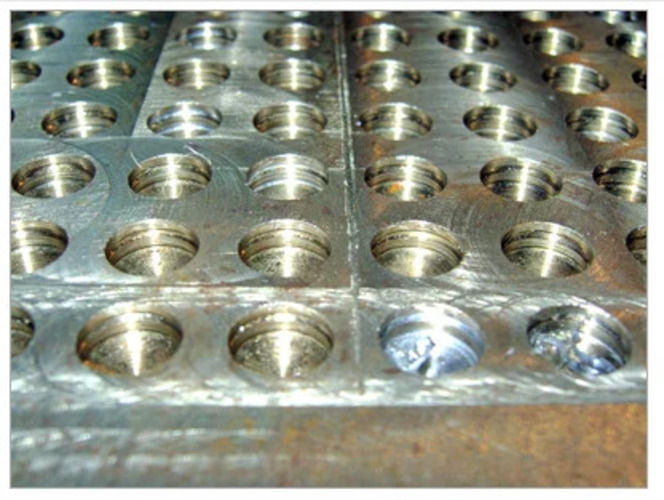

Precision Moulds for Medical Syringe Gaskets

Our Gasket Syringes Moulds are designed for heavy-duty use in industrial manufacturing plants, especially in medical and pharmaceutical settings. The application surface features a flawless mirror or high-polish finish, ensuring seamless product release and minimizing contamination risks. Utilizing advanced shaping modes for injection moulding, these moulds deliver exacting standards for syringe gasket components and reliably support high-volume production lines requiring uncompromised hygiene and precision.

Sample Policy and Delivery Insights

To facilitate your purchasing decisions, we offer a responsive sample policy, ensuring product inspection before full orders. Quotes are tailored swiftly to customer requirements, and our main domestic market covers all of India. Experience quick dispatch and prompt arrival on orders, with most deliveries completed within a brief timeframe. Clients benefit from our proactive service support, enabling hassle-free ordering, real-time tracking, and hands-on technical consultation throughout the process.

Precision Moulds for Medical Syringe Gaskets

Our Gasket Syringes Moulds are designed for heavy-duty use in industrial manufacturing plants, especially in medical and pharmaceutical settings. The application surface features a flawless mirror or high-polish finish, ensuring seamless product release and minimizing contamination risks. Utilizing advanced shaping modes for injection moulding, these moulds deliver exacting standards for syringe gasket components and reliably support high-volume production lines requiring uncompromised hygiene and precision.

Sample Policy and Delivery Insights

To facilitate your purchasing decisions, we offer a responsive sample policy, ensuring product inspection before full orders. Quotes are tailored swiftly to customer requirements, and our main domestic market covers all of India. Experience quick dispatch and prompt arrival on orders, with most deliveries completed within a brief timeframe. Clients benefit from our proactive service support, enabling hassle-free ordering, real-time tracking, and hands-on technical consultation throughout the process.

FAQs of Gasket Syringes Moulds:

Q: How do I choose between the cold and hot runner systems for Gasket Syringes Moulds?

A: Selecting between cold and hot runner systems depends on your production scale and specific application. Cold runners are often more cost-effective for shorter production runs, while hot runners offer efficiency and reduce material waste for high-volume manufacturing.Q: What is the mould cavity customization range available?

A: We offer cavity options from 4 to 32, with 12 as the standard. Customization allows you to match your production requirements precisely, ensuring both flexibility and scalability in your manufacturing process.Q: When can I expect delivery after placing an order?

A: Orders are processed with quick dispatch, and arrival times are minimized to ensure you receive your moulds promptly. Specific delivery times are provided at quotation based on order customization and location.Q: Where can these Gasket Syringe Moulds be applied?

A: These moulds are ideally suited for medical and pharmaceutical manufacturing plants, producing syringe gaskets from medical-grade polypropylene and silicone rubber, meeting stringent hygiene and precision standards.Q: What surface finish is available for the moulds, and why is it important?

A: You can choose between high polish and mirror finish surfaces. These finishes promote easier release, minimize product defects, and help maintain the sanitation required in medical-grade production.Q: How does the optimized water cooling circuit benefit the moulding process?

A: The optimized water cooling circuit ensures rapid, even cooling, leading to faster cycle times and reducing the risk of product warping, enhancing overall productivity and product quality.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry