Disposable Syringes Gasket Moulds

Disposable Syringes Gasket Moulds Specification

- Molding Material

- Silicone Rubber or Thermoplastic Elastomer (TPE)

- Cavity

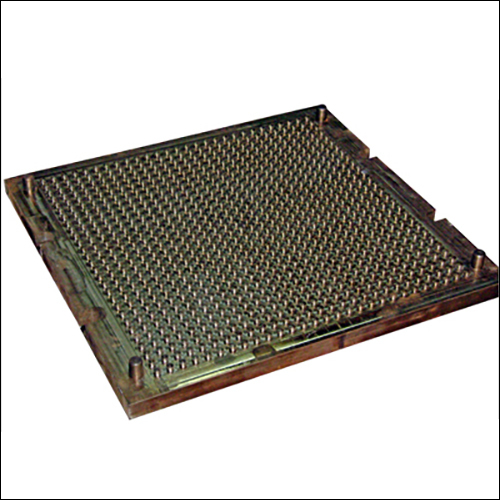

- 16 Cavities (Customizable)

- Mold Base

- P20 Steel / LKM Standard

- Shaping Mode

- Injection Mould

- Tolerance

- 0.01 mm

Disposable Syringes Gasket Moulds Trade Information

- Minimum Order Quantity

- 1 Set

- Payment Terms

- Cheque

- Packaging Details

- As per requirement

- Main Domestic Market

- All India

- Certifications

- An ISO 9001:2000 Certified company

About Disposable Syringes Gasket Moulds

Being a customer focused organization, we are engaged in manufacturing, exporting and supplying a superlative range of Disposable Syringes Gasket Moulds. These moulds are offered after passing through various quality tests so as to ensure that our clients are delivered with best grade and defect free range only. In order to attain utmost satisfaction of our valued patrons, we have been manufacturing these moulds in various shapes and dimensions. Adding to this, our highly prompt carriage & freight agents deliver these Disposable Syringes Gasket Moulds at patrons specified locations within predefined time frame.

Features:

-

Dimensional accuracy

-

Sturdy construction

-

Longer functional life

-

Corrosion resistant

Highly Customizable for Your Production Needs

Our moulds offer full customization in cavity number, size, and design, accommodating varied syringe gasket production requirements. The options for hot or cold runner systems and the choice between silicone rubber or TPE molding materials add to the flexibility, ensuring optimal alignment with your manufacturing process.

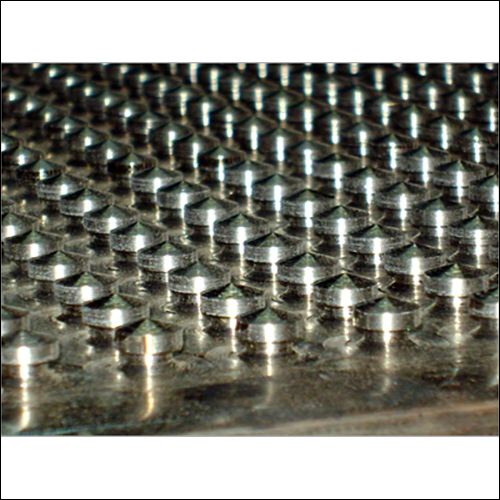

Precision Engineering with Efficient Processes

With a tolerance of 0.01 mm and a high gloss polish finish, every gasket produced meets stringent quality and aesthetic standards. Automated ejection via air and pins plus water cooling channels streamline the production cycle, improving output and reducing waste for syringe manufacturers.

Advanced Design and Durable Construction

Developed using industry-leading design software (UG, PRO/E, AutoCAD), these moulds are built on robust P20 steel or LKM standard bases. This ensures long-lasting durability and consistent mould performance, supporting continuous operations in high-volume settings.

FAQs of Disposable Syringes Gasket Moulds:

Q: How are the disposable syringes gasket moulds customized to suit specific production requirements?

A: We customize each mould based on your required cavity number, gasket size, and design specifications. Our team consults with clients to tailor the runner system (hot or cold), cavity arrangement, and dimensions, ensuring a precise fit for your syringe manufacturing line.Q: What materials are compatible with these gasket injection moulds?

A: Our disposable syringe gasket moulds are compatible with silicone rubber and thermoplastic elastomer (TPE), providing versatility to meet diverse production needs commonly found in medical and pharmaceutical manufacturing.Q: When should I choose a hot runner versus a cold runner system for gasket moulding?

A: The choice depends on production volume and material stability. Hot runner systems are ideal for high-volume runs and reduce material waste, while cold runners are suitable for lower volumes or when handling thermally sensitive materials.Q: Where is the production of these syringe gasket moulds carried out?

A: Manufacturing, export, and service provision of these moulds are managed from our facilities located in India, equipped with advanced tooling and design resources to ensure top-quality outputs.Q: What is the process for producing gaskets with these moulds?

A: Production follows the injection moulding process, where silicone rubber or TPE is injected under controlled pressure into the mould cavities. The efficient water cooling and automated ejection systems ensure smooth, continuous, and precise production.Q: How do high gloss polish and tight tolerance benefit syringe gasket manufacturing?

A: A high gloss polish ensures easy demoulding and improved surface quality of gaskets, while a tight tolerance of 0.01 mm guarantees dimensional accuracy. This results in reliable sealing performance and a high standard of finished medical products.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Syringes Gasket Mould Category

Disposable Syringes Mould

Minimum Order Quantity : 1 Set

Molding Material : Plastic, PC, PP, PE, Medical Grade Material

Tolerance : 0.01 mm

Mold Base : P20, 45#, S50C, LKM, HASCO, DME or as per requirement

Shaping Mode : Injection Mould

Mould Life : Minimum 1 million shots

Syringes Gasket Moulds

Minimum Order Quantity : 1 Piece

Molding Material : Plastic, Rubber, Silicone

Tolerance : 0.01 mm

Mold Base : P20 steel / Customized as per requirement

Shaping Mode : Injection Mould

Send Inquiry

Send Inquiry